Ulision Process

UEP utilized two process of plating in Zinc Electroplating which are Rack & Barrel.

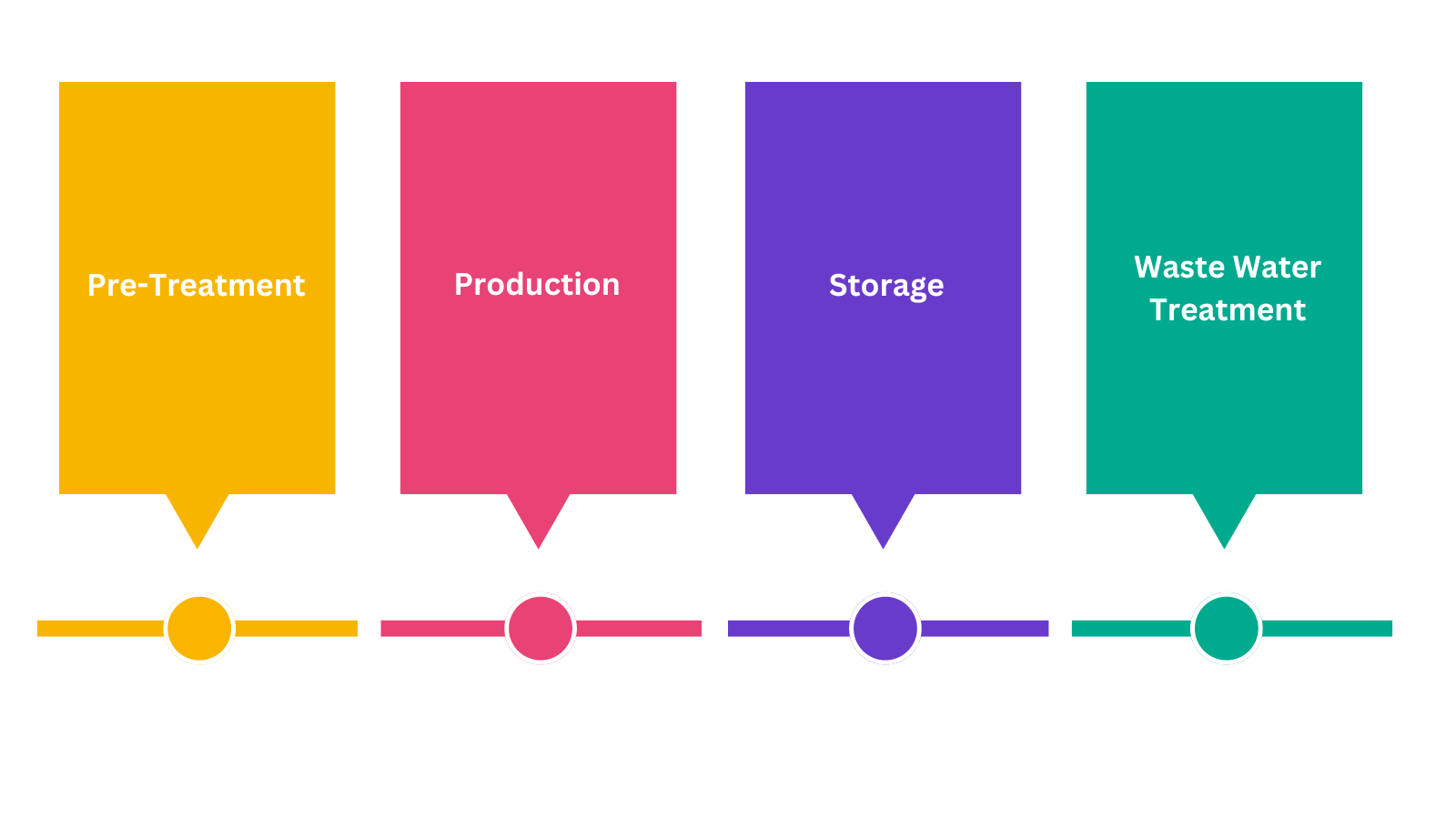

The plating processes basically consist of three stages, i.e.

Zinc Rack Plating

Zinc Rack plating is a process used to plate large, delicate or complex parts that cannot be finished through barrel plating.

Zinc Barrel Plating

Zinc Barrel Electroplating is the electrodeposition of dissolved zinc onto the surface of metal parts.

Zinc Nickel Alloy Plating

Ulision’s zinc nickel coatings (12 - 16% Ni) provide superior corrosion protection to red rust compared to pure zinc coatings.

Zinc Flake Coating

Alternative to Zinc or Zinc Alloy Plating. Zinc Flake coating is a method to deposit electroless a cathodic protecting layer by applying a lacquer system.

Black Oxide Coating

Black oxide is a conversion coating used mainly on iron & steel. It results in a black, smooth surface finish, and improves corrosion resistance and wear resistance.

Pre-Treatment

Pre-treatment is the preparation of the item for the actual plating step, and typically done in two processes:

Plating

Zinc Rack plating is a process used to plate large, delicate or complex parts that cannot be finished through barrel plating.

Post-Treatment

Zinc Rack plating is a process used to plate large, delicate or complex parts that cannot be finished through barrel plating.

Pre-Treatment

Pre-treatment is the preparation of the item for the actual plating step, and typically done in two processes:

1. De-scaling / De-rusting

This is done by soaking the items in an acid (usually HCL) to remove heat treatment scales,mill scales, rust, burnt oil , etc.

Note: Over pickling due to too high concentration of acid or excessive time will result in parts damage such as parts become under size or thread and body got corroded. Under pickling will result in insufficient plating coverage or blistering.

Concentration of HCL approx.30%-50%. Time : 1-10mins

2. Degreasing

This is done by soaking the item in a tank or rolling the items in a barrel in an alkaline cleaner solution to remove oil or grease. Please note that scales and oil or grease must be thoroughly cleaned before plating or it will result in un-plated sports, blistering or peeling. Bigger items for rack plating need to be hand scrub after soaking.

Production Area ( Auto Barrel Line)

Waste Water Treatment

A waste water treatment plant is installed in UEP and complied to Malaysia DOE regulations

Watch How We Work

Address:

No.1 Solok Selat Selatan 21A, Sobena Jaya Industrial Estate, Pandamaran, 42000 Port Klang, Selangor Darul Ehsan Malaysia

Email:

ulision@ulisionep.com sunkh@ulisionep.com

Open Hours:

Mon-Sat: 8am - 5pm